Hi, I’m H., and I’m from the IT Technology Division.

As we’ve mentioned before, Sugitec is all about “high-quality education for all,” which is one of the SDGs goals. They’ve been holding regular educational opportunities in the form of in-house meetups, where staff from other departments can casually participate in study sessions.

This time, we got together online from the Tokyo branch to talk about the epoxy resin injection method, which is a way to repair tiled exterior walls and replace tiles.

This year’s meetup is all about the injection method

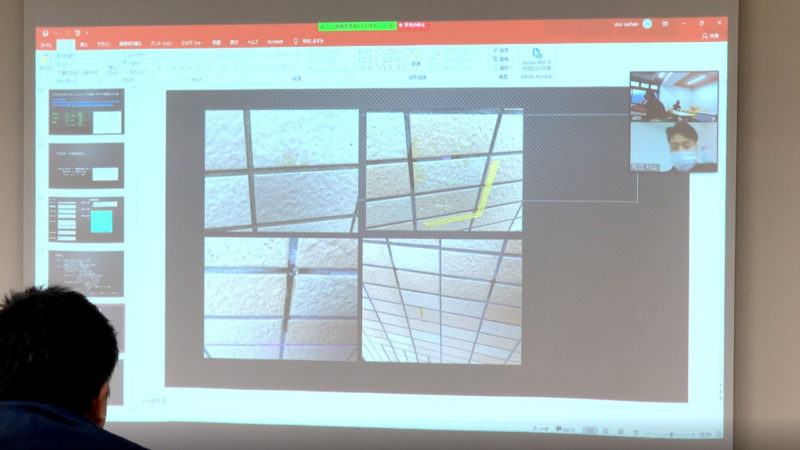

When it comes to fixing floating exterior wall tiles, a technique called anchor pinning is often used to stop the tiles from falling out because they’re peeling or for other reasons.

This method involves using a vibration-free drill to create holes in areas where there is floating. The holes are then filled with epoxy resin. Finally, an anchor pin is inserted into the hole to secure the tile in place and prevent it from peeling off.

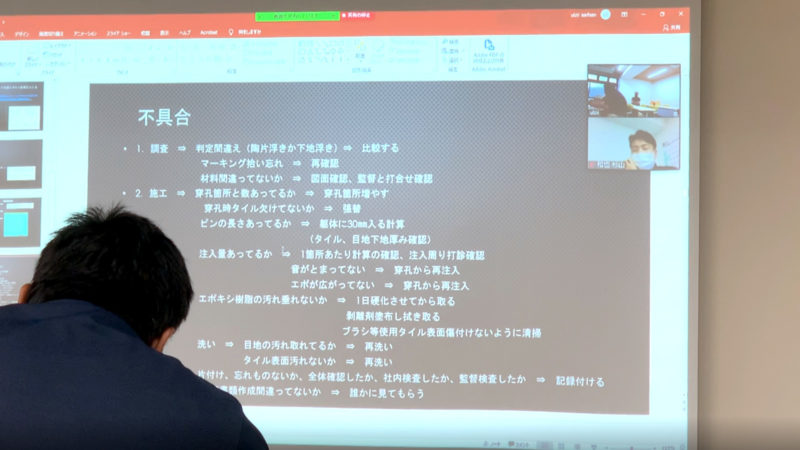

In today’s lecture, we’ll be talking about why defects happen, from the initial investigation stage to the construction stage, as well as what we can do to avoid them after the project is finished.

The anchor pinning method is a method that’s pretty common in the construction department, but there are lots of things that can affect the quality of the finished product if you’re not careful. It was useful to share not only the general items to check, but also points to check based on the experience of experienced workers.

Summary

In my day-to-day work, I often have to check my own work, and I think this applies to work in a variety of industries as well. I believe that each of us was able to recognize the importance of checking not only the technical aspects of our work, but also the obvious things.